Banner Photo by Tiago Gerken

Have you ever wondered the most cost effective way to build & maintain a railway line?

Probably not, but if you’re in the business of managing railway lines this sort of information can save millions.

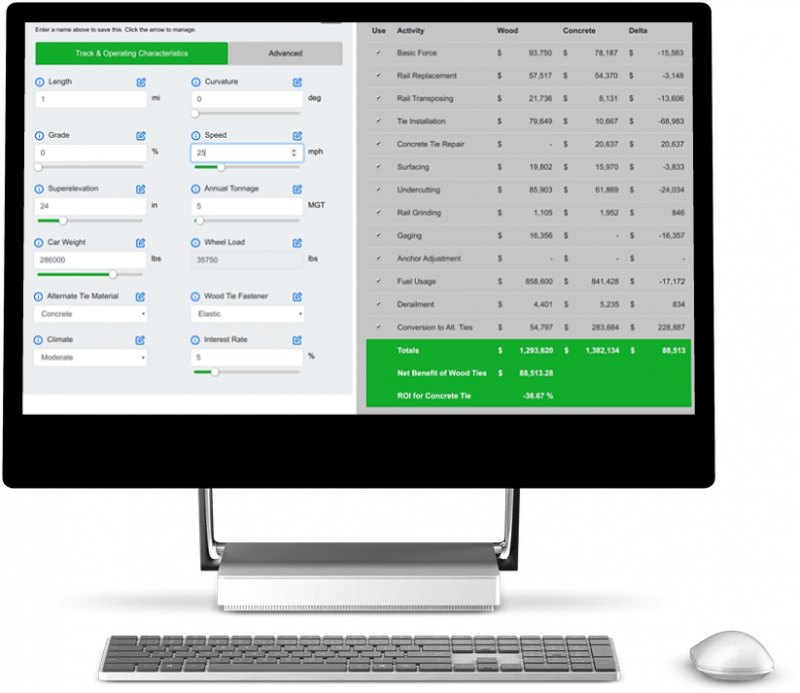

So it was an interesting experience to build “SelecTie III” - a railway costing tool for calculating the cost of railway construction & maintenance.

I really enjoy projects like this which make me think hard about problems I didn’t know existed & how to solve them.

In this case the problem is:

There are a number of different materials that can be used as railway sleepers (or railway ties, if you’re American) but each has it strengths & weaknesses. Each railway line is unique in the geology traverses & the amount of use the line is going to get.

So how do you match a railway line with the correct railway tie material? Keeping in mind that getting things wrong could result in overspending on building & maintenance or could even structural failure or derailment.

To help railway line managers make the right decision the Railway Tie Association had developed a scientific/ engineering model that took in all the information about the railway line - both it’s physical structure & use - and returned pricing for different tie materials.

So far so good but they needed a way to make that model accessible to railway line managers. It needed to be accessible & easy to alter characteristics to assess the best material for the job.

UpShift was approached for this job & we set about turning a complex model into a user friendly web app.

Taking over 80 possible inputs & turning them into an interactive app was a challenge but I’m really pleased with the end result. Even a layperson can see how different railway factors affect the cost of different materials.

The SelecTie tool is currently hosted by Oregon State University if you want to price your very own railway: https://rta-selectie.forestry.oregonstate.edu/